Highest quality coupled with outstanding performance has a name: MOTOMAN

Robotic Systems

Turnkey solutions and custom systems

Arc-Welding Systems

Turnkey arc welding systems with MOTOMAN industrial robots, application-specific products and safety equipment

> Download Brochure ArcWorld Family

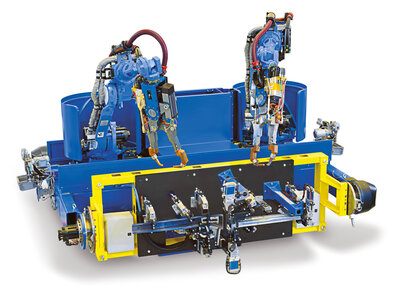

Read moreSpot Welding Systems

The core of this system are the MOTOMAN robots specialised on spot welding applications with servo motors built in-house.

Mounted on a new positioner, they are saving space up to 40 % and provide better accessibility and high cycle times.

Key benefits

- Improved accessibility to the parts to be welded

- Flexible concept – high versatility from one product to another

- “Robot on board” in frontal position, easy unloading of the item without interference

Download Brochure "Spot Welding Solutions"

Read morePressbrake Systems

For a production that mainly consists of large and heavy parts, Yaskawa offers a standard press-brake system with robots of up to 180 kg payload.

Read morePallet Repair Systems

Start of pallet repair is always dismantling of damaged parts.

Yaskawa offers a system for automated hydraulic removal of blocks, stringers or leading boards from Euro pallets with MOTOMAN industrial robot.

The operator chooses on a touch screen the damaged parts, and the machine dismantles them automatically.

Our turn key systems can work stand alone, combined with sorting systems or be integrated in your existing conveyor network.

These systems reduce manual work, mainly lifting pallets and using the tiger saw.

Read more