Highest quality coupled with outstanding performance has a name: MOTOMAN

Metalworking

Yaskawa Ireland Applications By Industry Metalworking

Overview

Best performance for every process

The machining of metals presents a multitude of challenges for automation: precision and high throughput with durable, low maintenance technology. With best-in-class products and an open and ready-to-connect architecture, Yaskawa creates important prerequisites for excellent and energy-efficient solutions. And has done so for decades.

Energy-efficient inverter drives for spindle, winder and transport

Whether in control cabinets or on the wall, in a clean or harsh environment: the flexible product design of Yaskawa AC Drives ensures reliable operation under a wide range of environmental conditions.

Energy-efficient and powerful spindle drives are easy to implement with Yaskawa AC drives. With an output frequency of up to 1000 Hz and corresponding gearboxes, spindle applications up to high-speed range are possible.

A special edition of our inverter drives meets the special requirements of winding and unwinding systems. Asynchronous and permanent magnet motors can be controlled with or without speed sensor and enable precise winding of textiles, paper, foils, wires etc.

Limitless possibilities

- Flexible motor control, extensive and expandable functions and a power range up to 630 kW: V1000 and

- A1000 AC drives and the successor GA700 are suitable for a wide range of applications, from simple conveyor belts to complex systems with networked drives.

Easy integration into your control system

- Supports all common protocols and topologies

- Cost-effective networking of up to five frequency inverters via a single fieldbus card

Cost savings through built-in interface

- RS-485 MEMOBUS/Modbus Protocol

- Communication speeds of 115.2 kBit/s

Servo drive technology for high-precision cutting and forming

With more than 12 million servo systems installed worldwide, Yaskawa has extensive experience and technical know-how in the field of motion control. The result: Excellent performance and an extremely low failure rate.

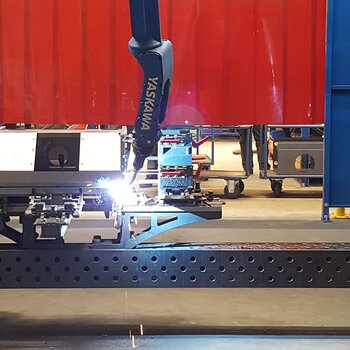

Precise plasma cutting

High torque combined with highly efficient vibration suppression ensures extreme path accuracy even at high product throughput rates.

High throughput in bending presses

Sigma-7 servo motors position the back gauge in bending presses at lightning speed, thus ensuring a perfect result.

Enhanced vibration suppression

The previous functions for vibration suppression have been improved and extended to further optimize the settling time. This reduces vibrations and resonances during operation and stopping. This is reflected in the quality of the end products.

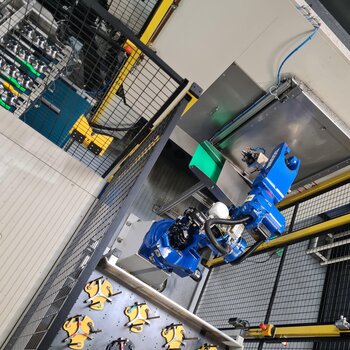

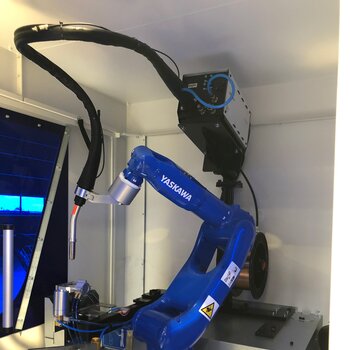

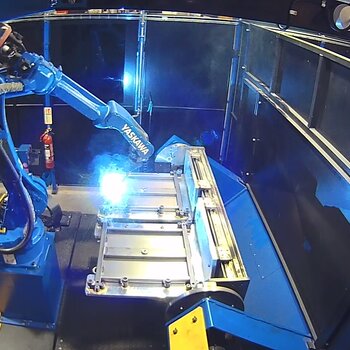

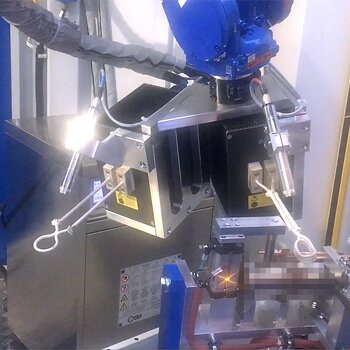

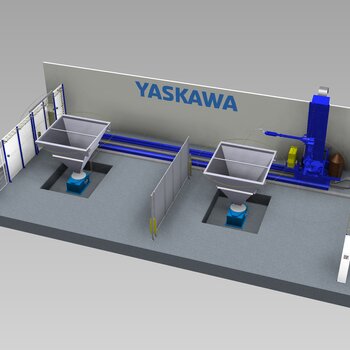

Robots for welding, cutting and handling

Yaskawa offers special welding robots, high-quality positioners and gantry systems up to complete welding systems. In addition, the Motoman robots from Yaskawa are also the optimum solution for handling and material feeding due to their speed, precision and cost-effectiveness.

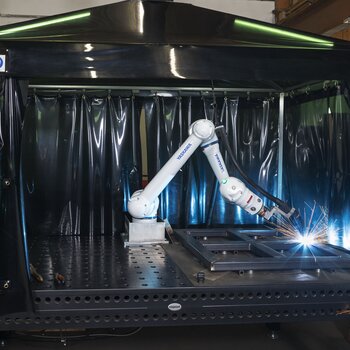

Turnkey welding systems

With more than 30 years of experience and a market share of over 30%*, Yaskawa is the No. 1 in automated path welding. For the development and construction of systems, as well as robot programming, Yaskawa offers an all-round package according to customer requirements.

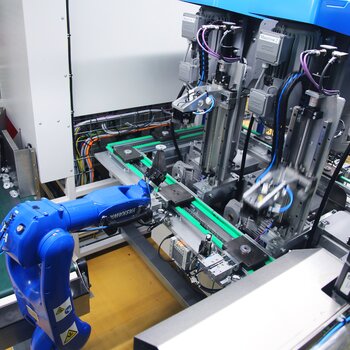

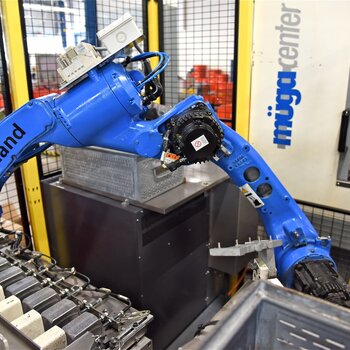

Material handling with robots

The Motoman MH series offers flexible, 6-axis highspeed robots for a variety of applications such as handling, machine loading, processing and distribution applications.

Solutions for metalworking

A robot is the universal tool for a multitude of machining operations:

- Handling

- Drilling

- Cutting

- Workpiece feeding

- Spot welding

- Arc welding

- Turn-key robot-based arc welding cells

Controlling and visualization

As machines become more powerful, it gets more important to monitor the condition of machines continuously and precisely. Machine controllers and integrated motion controllers from Yaskawa offer the optimum solution for every type of application. ecoPanels, professional panels and even panel PCs from Vipa Controls provide suitable operating concepts for human-machine interaction.