Highest quality coupled with outstanding performance has a name: MOTOMAN

MiniTec automates HMT cleaning system with eight MOTOMAN GP robots

Automation – a clean job

To be able to react better to fluctuating order volumes, specialist company HMT automated its MiniTec industrial parts cleaning system to a greater extent - with clear success.

- Industries

- Automotive

- Applications

- Material Handling

- Client

- MiniTec GmbH

- Products

- GP Series

- GP12 - GP Series

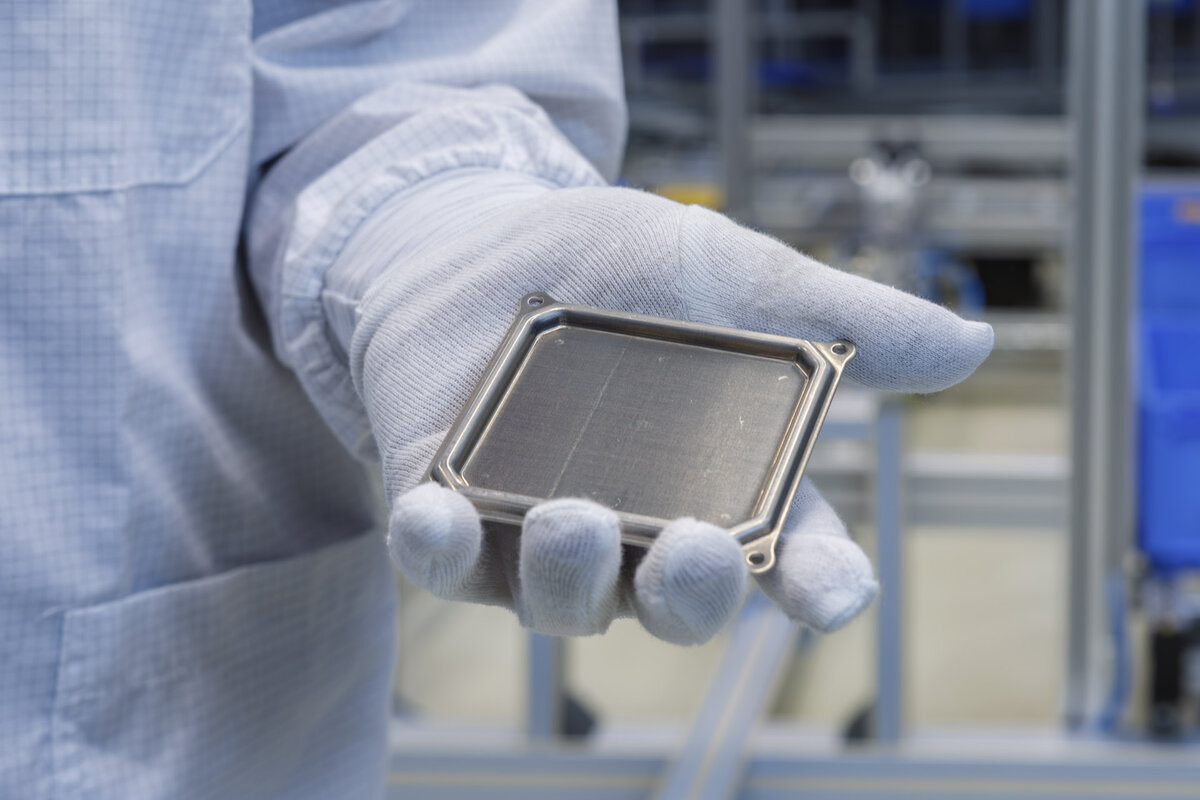

"Not just clean, but pure" was once the promise of a well-known German detergent advertisement. HMT (Häseler Metalltechnik GmbH) in St. Georgen makes a similar claim when it comes to cleaning technical components. Founded in 1983, the company specializes in stamping and forming technology, as well as cleaning components with very high technical cleanliness requirements. Its customers are primarily in the automotive sector. The workpieces are primarily stamped parts that come into contact with electrical components and circuit boards.

Joachim Hölzl, the company's technical managing director, describes an all-in-one solution offered by HMT: "We have punching and cleaning under one roof in a 12,500-square-meter area. Our services include stamping, forming, deep drawing, and parts cleaning, as well as residual dirt analysis in our own laboratory. We can fulfill almost any customer request. This is made possible by our own toolmaking department, modern machinery, and dedicated employees with in-depth knowledge. Our processes and procedures meet the highest automotive standards."

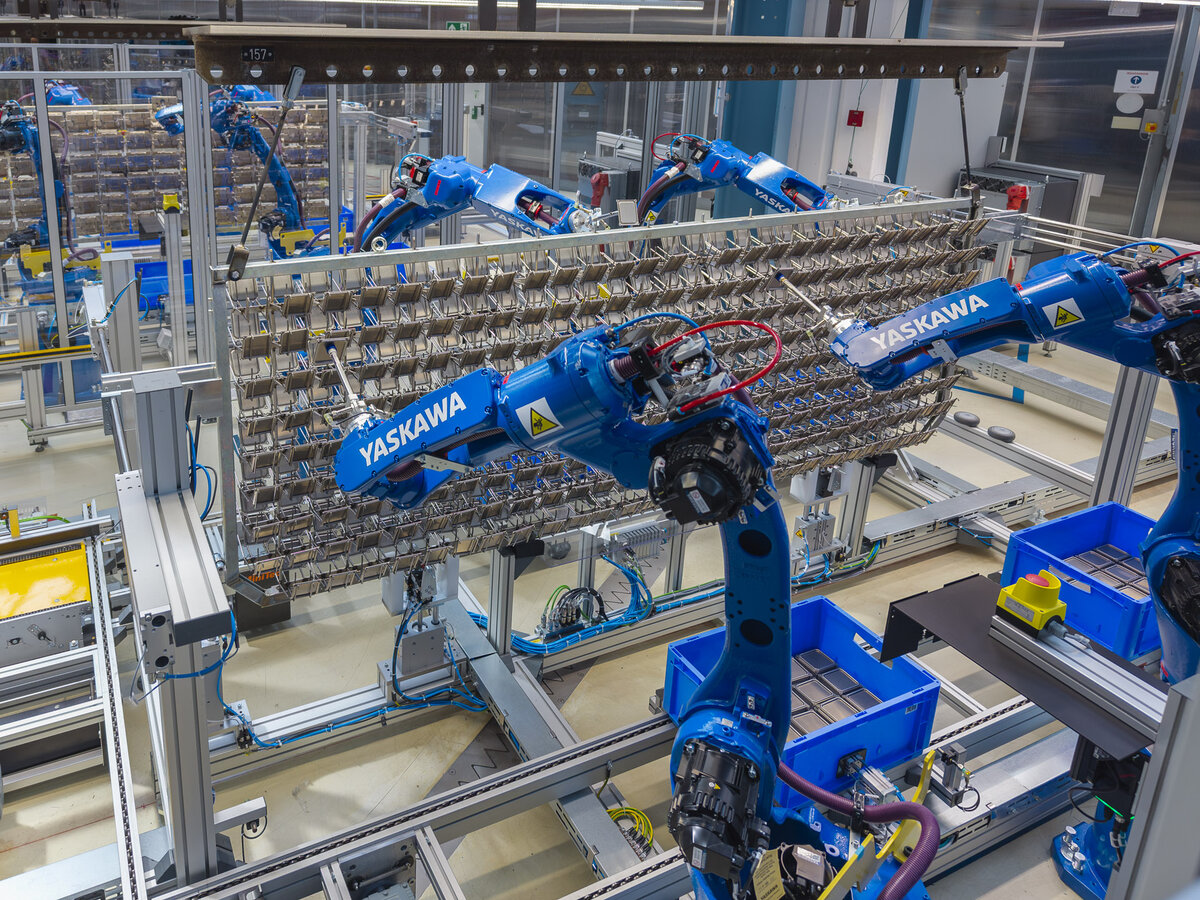

Picture: Eight MOTOMAN GP12 robots then remove the components and place them in SLCs.

Fluctuating order backlog is a challenge

HMT uses two cleaning systems. Work is carried out in two shifts at normal capacity, enabling around 40 million components to pass through per year. In the past, employees carried out many activities in the cleaning process. However, the general shortage of labor became increasingly noticeable. Partnering with personnel service providers did not provide a satisfactory solution. According to Joachim Hölzl, this was due to the volatile weekly changes in the order backlog: "This made it difficult to plan resources properly and react to new circumstances at short notice. One week demand increases, and by the time you have integrated the capacities via the staff, the week is almost over."

Looking ahead, Hölzl aims to plan and control this much more reliably and respond more flexibly to capacity fluctuations. The goal was to achieve this through increased automation, focusing on loading the transport racks with components for the cleaning process and subsequent removal.

Picture: The racks containing the components enter the cleaning system via an overhead conveyor.

Automation for more flexibility

The first step was to meet with in-house specialists under the leadership of Tobias Seemann, the team leader of the automation department at HMT. An ABC analysis of the components was drawn up and possible solutions were discussed. Hölzl explains: "We built our own internal laboratory and started the first trials with a training robot. The results were very impressive. We then contacted Yaskawa, who provided us with one of their robots for the next steps. Once we were confident in the project's feasibility, we partnered with MiniTec as the system integrator. We presented our vision to automation expert Peter Müller and discussed what the system could look like based on our requirements and specifications. He developed a concept for implementing the solution, which was then put into practice."

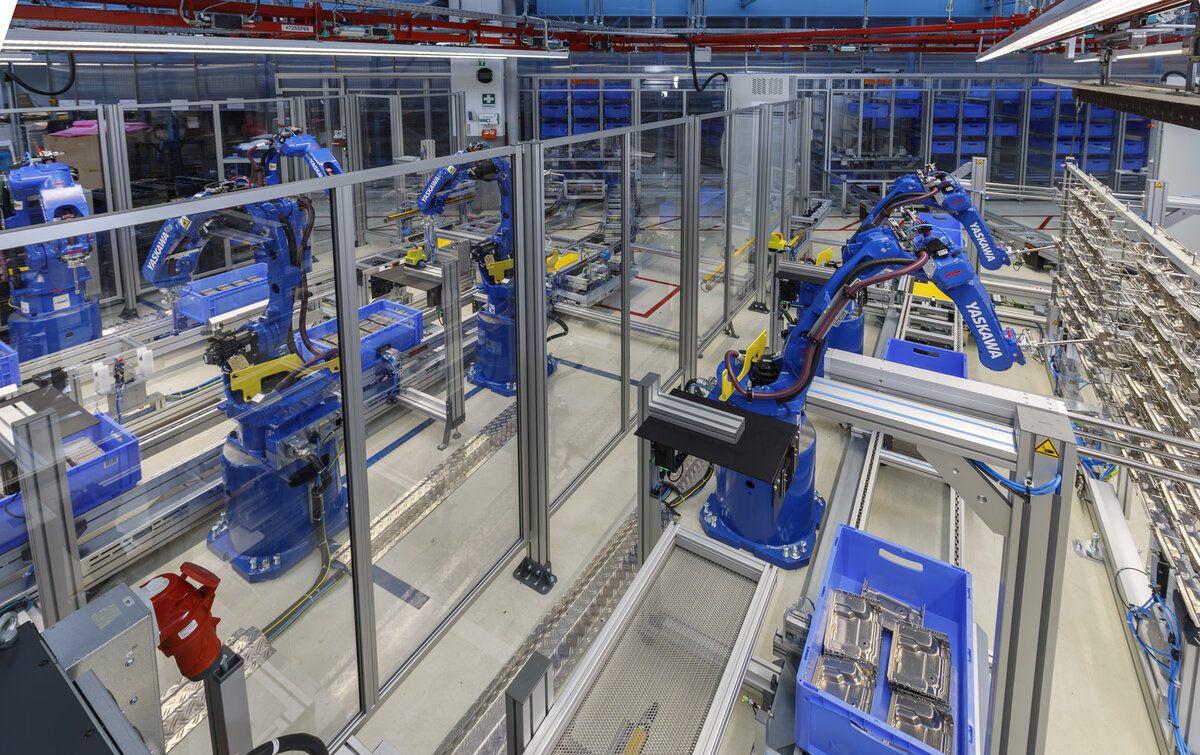

The result was a highly complex system in which the removal, storage, and retrieval of the cleaned components are fully automated. The design with two identical removal points ensures sufficient capacity. Eight MOTOMAN GP12 robots are used to remove the parts carriers. Robots in the GP series are characterized by high speeds, acceleration, and repeat accuracy. The entire system is linked to a fully automated storage system. With dimensions of 20 m x 10 m, the facility is quite large.

Picture: After cleaning, the racks automatically move to the correct removal point.

Today's procedure:

The customer's components to be cleaned are delivered to HMT in various types of packaging, such as mesh boxes, wooden boxes, and cardboard boxes. At the pickup point, the components are removed from the containers - still manually at this time - and fixed to cleaning racks.

The system then collects the racks from the intermediate storage. The racks pass through the cleaning process on an overhead conveyor in various zones over a length of 60 meters. Next, they go to the drying room, then the cooling room, and finally the clean room. Depending on the technical specifications of the components, the cleaning rack either remains for removal or moves to the clean room where removal stations with robots are located.

Since the components may move during cleaning, there may be differences between handles when the robot removes them. For this reason, a camera check is carried out to define the coordinates and ensure the components are placed correctly in the SLCs (Small Load Carriers). This ensures that the order of the components is not lost when they are transferred to other departments.

Picture: A camera inspection ensures the components are placed correctly in the SLCs during removal.

Sophisticated control system

During loading, the cleaning racks receive barcode information about which parts are involved and which removal station they must travel to. At the picking station, item-specific information is transferred via an interface between the cleaning system and the robot cells. Joachim Hölzl explains: "This means the robot knows exactly which component is coming and in what quantity. It also knows how much to remove. If a component is lost, the robot calculates the target number minus one. This ensures that the correct number of pieces is always removed."

Picture: The components to be cleaned mainly come from the automotive sector.

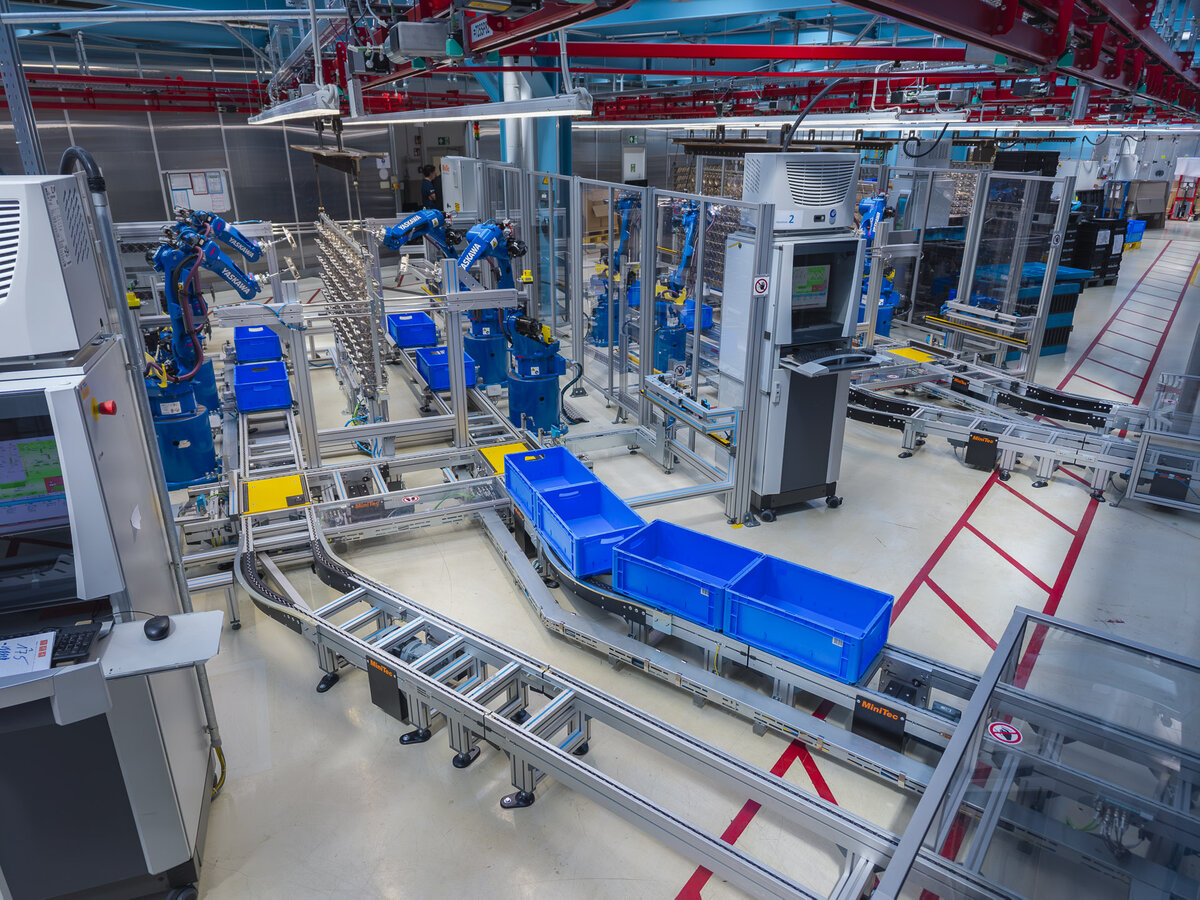

Automatic conveyor technology from MiniTec

Each robot has an SLC in front of it. It removes components from the cleaning rack and places them correctly in the box. Once the specified quantity is reached, the SLC automatically moves out, and the robot is provided with an empty box.

The filled SLC then travels along a conveyor line to a storage rack. The conveyor technology is an FMS system from MiniTec. In other words, it is a transfer system in which the boxes are transported via curves or turntables. A special feature of the HMT version is that it does not use workpiece carriers, or pallets; instead, the SLCs are driven directly by roller chains.

Picture: The filled SLCs travel via an FMS conveyor line from MiniTec to the storage rack. Empty boxes are then returned to the robots.

Storage and retrieval are performed by a shuttle.

A storage and retrieval unit (shuttle), also developed by MiniTec, is attached to the storage rack. It automatically stores the SLCs and travels back and forth. It also transports components for visual inspection. There is a control station in this area where employees can see which components are in the storage system. Employees can then request the parts to be tested via a control panel. The shuttle starts the retrieval process, making the SLCs available for visual inspection via a conveyor system. There, the parts are inspected according to the customer's error catalogs. If they are OK, they are packed in the customized packaging.

Picture: The fully automatic storage system from MiniTec.

Significantly increased flexibility

Joachim Hölzl felt the benefits of the system after the initial startup: "The biggest benefit is flexibility. Today, we have the decisive advantage of being able to increase capacity at any time, even at the last minute."

Hölzl is also satisfied with the project's progress: "The collaboration among the three-person team of MiniTec, Yaskawa, and HMT worked very well and ultimately produced an excellent result. As mentioned, Yaskawa supported us by making a robot available to us. MiniTec also provided intensive support as a system integrator. They helped with simulations, cycle times, and other related topics. It was an absolutely great collaboration, especially with Peter Müller. His experience in project management and technical expertise added enormous value, especially for HMT.

Picture: A shuttle takes care of storing and retrieving the SLCs with components.

Tobias Seemann and Peter Müller were a terrific combination. I really appreciated the communication, project development, and MiniTec's experience. Many ideas were also developed during the project. Small improvements were always found, which we then implemented quickly. Marcel Therre and Phillip von Ehr were also great contributors and absolute team players.

Picture: There is sufficient capacity thanks to two identical removal stations with a total of eight MOTOMAN GP12 robots.

Further expansion of automation is the goal.

In general, the HMT boss is open to automation. He is already considering switching from manual to robotic loading of the cleaning racks. Another topic is removing components in the clean room. "We have many approaches here, not just in production. There are also numerous automation options in administration, some of which we have already implemented. In the future, we want to examine all areas to determine which processes can be automated to minimize human error." Accordingly, the automation department has grown to include four people. Due to their positive experiences, Yaskawa and MiniTec will also be back on board in the future.

Picture: Thumbs up for the new automation solution (from left): Stefan Wache (MiniTec), Simon Bublies, Moritz Benzing and Joachim Hölzl (all HMT).

Author:

Stefan Wache

Head of Marketing and Communication

MiniTec GmbH

Contact for readers’ enquiries:

Phone +49-8166-90-0

robotics@yaskawa.eu

www.yaskawa.de

MiniTec GmbH

P +49-6373-8127-0

Stefan.Wache@minitec.de

www.minitec.de